Research Spectre Powerboats Boats

About Spectre Powerboats Boats

170 W. Election Rd Suite 100

170 W. Election Rd Suite 100Draper, ut 84020

About Spectre Powerboats

Quality, History and Performance

From its roots as a premier boat manufacturer going back to the 80s, Spectre boats quickly became known for its performance excellence and attention to detail.

Spectre boats impressive list of credentials includes:

*APBA Offshore World Championship winner

*2-time Super Boat International winner

*Kilo record holder for both APBA and Super Boat International

*Recipient of 3 Powerboat Magazine Product Excellence Awards

Spectr e boats constantly evolving designs and use of state-of-the-art construction materials, techniques, and hardware position the company at the fore-front of the high-performance powerboat market.

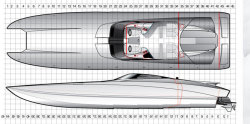

~Design

This is where it all begins. Frequently, a new boat design is an evolution of a previous successful design, with the purpose of adding new features and changing or improving specific performance characteristics. Having determined the overall boat design, features, and desired performance characteristics of the boat, computer models and analytical tools are used to help fine-tune the design. CAD drawings and blueprints are ultimately created.

~Tooling

Following the design specifications, our master carpenters and designers create a plug, from which a mold can be built. The plug is precision engineered to exacting specifications, as it is from the mold of this plug that all other boats will be made. Separate molds are made of the hull and deck and of other components such as center consoles, cockpit liners etc.

~Assembly

Deck and hull are assembled using Plexus Fiberglass Fusion adhesives, which chemically fuses the deck and hull together at a molecular level. This actually creates a bond that is stronger than the fiberglass/resin itself. The result is a stronger, lighter, faster boat. An additional fiberglass layer is applied to the joint, and then through-bolted.

~Rigging Department

It is here that the boat receives all of the mechanical components. Utilizing only aircraft-rated stainless steel Allen head bolts or sockets with nyloc nuts, all hardware is through-bolted. We take special pride in our rigging. For example, you will notice that all the screw heads on the rubrail are aligned in the same direction.

In the lamination phase we embed mounting plates in the hull and deck to accept certain hardware. This makes for a solid and durable anchor point.

Mercury Marine Engines are installed.

A wide variety of gauges and electronics such as those from Livorsi and Garmen are also fitted at this stage.

All wire looms are custom made in house and are supported by stainless steel cushioned clamps. All wiring is shrink sealed and enclosed in conduit to insure against possible wear. Our wiring is second to none when it comes to quality of installation. We take pride in what we do and how we do it.

~Interior Install

We use only the finest grade of marine vinyl fabrics. Our foam is the best available. Our snap-in carpet is 40 oz. marine grade plush pile. All seat bases are fiberglass, billet aluminum no wood is used here! All staples are stainless steel. Each set of upholstery is custom made, embroidered with the Spectre boats logo.

~Lake Test

Each boat is water tested at the fresh water Lake Tarpon. Here we make sure that all fittings and connections are water-tight and that all systems work in a real world environment, not just on the trailer. We also fine-tune the motor to optimum settings and dial in the correct propeller to match the customers desired needs.

Quality, History and Performance

From its roots as a premier boat manufacturer going back to the 80s, Spectre boats quickly became known for its performance excellence and attention to detail.

Spectre boats impressive list of credentials includes:

*APBA Offshore World Championship winner

*2-time Super Boat International winner

*Kilo record holder for both APBA and Super Boat International

*Recipient of 3 Powerboat Magazine Product Excellence Awards

Spectr e boats constantly evolving designs and use of state-of-the-art construction materials, techniques, and hardware position the company at the fore-front of the high-performance powerboat market.

~Design

This is where it all begins. Frequently, a new boat design is an evolution of a previous successful design, with the purpose of adding new features and changing or improving specific performance characteristics. Having determined the overall boat design, features, and desired performance characteristics of the boat, computer models and analytical tools are used to help fine-tune the design. CAD drawings and blueprints are ultimately created.

~Tooling

Following the design specifications, our master carpenters and designers create a plug, from which a mold can be built. The plug is precision engineered to exacting specifications, as it is from the mold of this plug that all other boats will be made. Separate molds are made of the hull and deck and of other components such as center consoles, cockpit liners etc.

~Assembly

Deck and hull are assembled using Plexus Fiberglass Fusion adhesives, which chemically fuses the deck and hull together at a molecular level. This actually creates a bond that is stronger than the fiberglass/resin itself. The result is a stronger, lighter, faster boat. An additional fiberglass layer is applied to the joint, and then through-bolted.

~Rigging Department

It is here that the boat receives all of the mechanical components. Utilizing only aircraft-rated stainless steel Allen head bolts or sockets with nyloc nuts, all hardware is through-bolted. We take special pride in our rigging. For example, you will notice that all the screw heads on the rubrail are aligned in the same direction.

In the lamination phase we embed mounting plates in the hull and deck to accept certain hardware. This makes for a solid and durable anchor point.

Mercury Marine Engines are installed.

A wide variety of gauges and electronics such as those from Livorsi and Garmen are also fitted at this stage.

All wire looms are custom made in house and are supported by stainless steel cushioned clamps. All wiring is shrink sealed and enclosed in conduit to insure against possible wear. Our wiring is second to none when it comes to quality of installation. We take pride in what we do and how we do it.

~Interior Install

We use only the finest grade of marine vinyl fabrics. Our foam is the best available. Our snap-in carpet is 40 oz. marine grade plush pile. All seat bases are fiberglass, billet aluminum no wood is used here! All staples are stainless steel. Each set of upholstery is custom made, embroidered with the Spectre boats logo.

~Lake Test

Each boat is water tested at the fresh water Lake Tarpon. Here we make sure that all fittings and connections are water-tight and that all systems work in a real world environment, not just on the trailer. We also fine-tune the motor to optimum settings and dial in the correct propeller to match the customers desired needs.

Results: 1 - 4 of 4

Page: [1]

2012 - Spectre Powerboats - SC30

Year:

Make: Spectre Powerboats

Model: SC30

Length: 30 feet 0 inches

Location:

See Boat Details

View

Contact Seller

2012 - Spectre Powerboats - SC32

Year:

Make: Spectre Powerboats

Model: SC32

Length: 32 feet 0 inches

Location:

See Boat Details

View

Contact Seller

2012 - Spectre Powerboats - SCX36

Year:

Make: Spectre Powerboats

Model: SCX36

Length: 36 feet 0 inches

Location:

See Boat Details

View

Contact Seller

2012 - Spectre Powerboats - SCX43

Year:

Make: Spectre Powerboats

Model: SCX43

Length: 42 feet 0 inches

Location:

See Boat Details

View

Contact Seller

Results: 1 - 4 of 4

Page: [1]